Five electric motor types

Simcenter E-Machine Design currently supports the following machine types via its design templates: synchronous, induction, switched reluctance, commutator, and axial flux. All templates can be easily modified, as they are fully parameterized. Automatic scaling is also available via the initial sizing function.

Electric machine phase windings

The winding layout plays a central role in machine performance. The technology used to determine the complete list of all possible balanced layouts is unique and makes evaluating alternatives easy. All the relevant factors are automatically calculated.

You can modify any predetermined layout, or manually describe the winding.

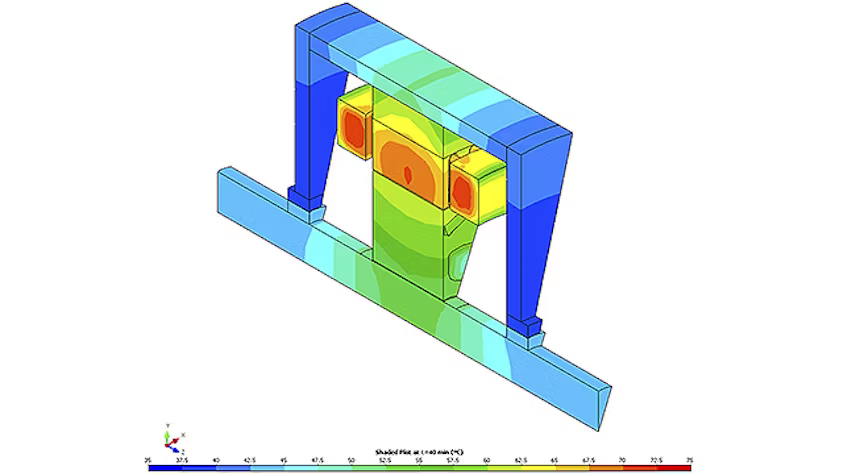

Motor thermal analysis

Leverage seamless co-simulation between electromagnetics and thermal analysis for electric machines to study the effects of heat and various cooling strategies on performance. Using a robust and highly proficient 3D FEM and a clearly defined operating duty cycle, the software provides transient temperature results which can be readily reviewed.

Conduct virtual experiments

Use preset virtual experiments to evaluate the simulated performance of electric machines. The experiments yield tables, charts, and shade plots of all necessary performance data.

The virtual experiments allow the user to analyze a range of operating points to fully characterize the machine.

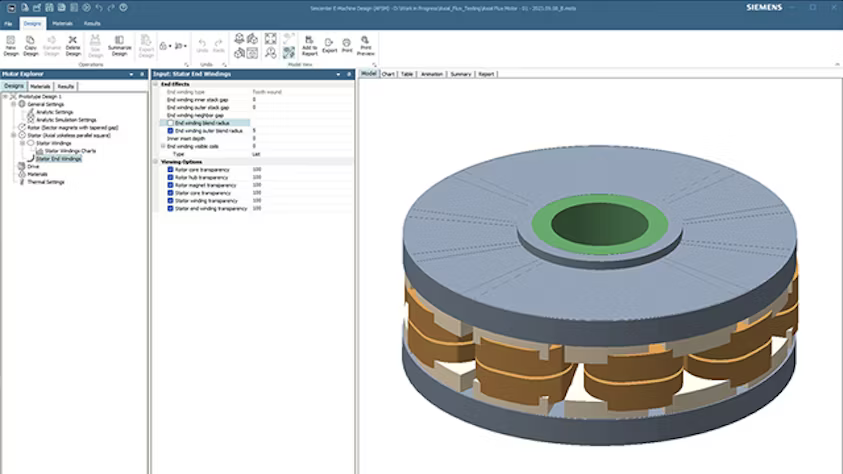

Quick and easy set-up via editors

Use the templates to quickly define the parameters of your Rotor and Stator for either radial or axial machines. Changes to the parameters are instantly displayed showing your new geometry.

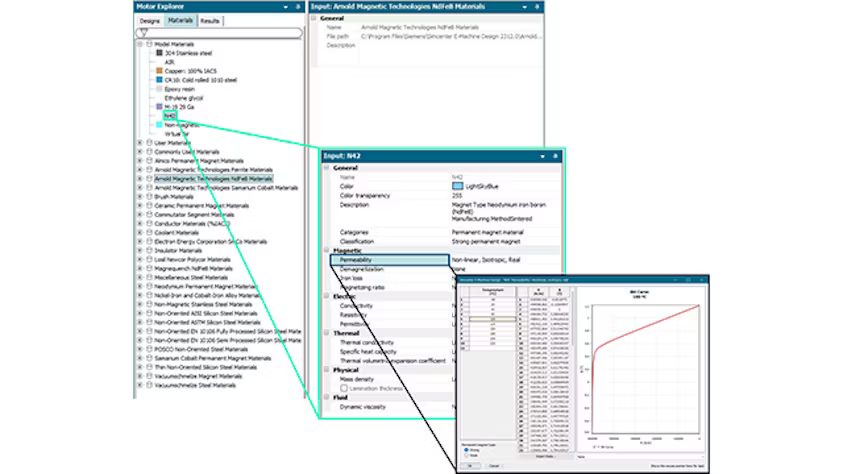

Flexible material databases

Test your design with different materials quickly with easy access to our database of materials. Our database includes independent libraries for each component of the machine. Assign lamination steels, magnets, or conductors from available libraries or enter your materials.