Linear Motors: Precision and Efficiency for Industrial Applications

The increasing demands for dynamics, accuracy, and synchronization in linear drive technology have led to the development of innovative solutions—foremost among them, the linear motor. Similar to torque motors as rotary direct drives, linear motors function as linear direct drives. In this setup, the load is coupled directly to the moving part of the motor, eliminating the need for mechanical transmission elements. This rigid mechanical coupling offers key advantages—well known from rotary direct drive technology—and opens up new possibilities for machine design.

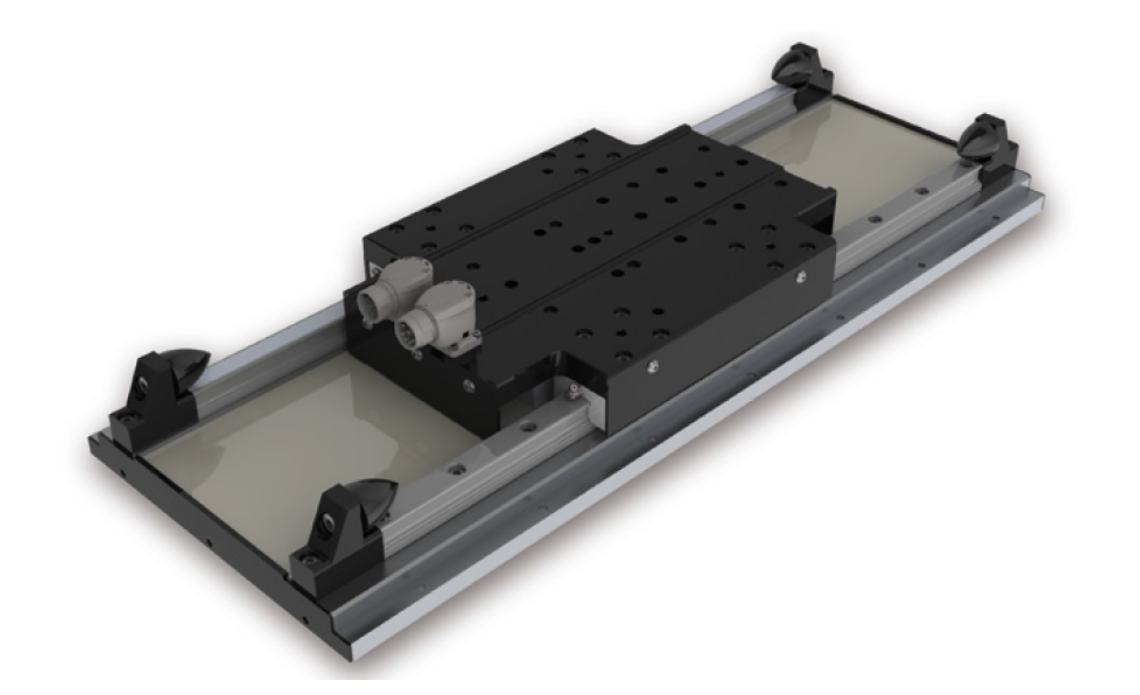

We offer a wide range of linear motors in various sizes and types, covering forces from 3 N to 16,000 N. Our linear motors are ideal for a variety of industrial applications and provide multiple cooling options, including natural convection, air cooling, and water cooling.

Discover our high-performance linear motors that deliver maximum precision, efficiency, and flexibility tailored to your specific needs.