Kit motors, also known as built-in motors or kit motors, offer a unique type of drive technology where the motor itself does not have its own housing or bearings. Essentially, they consist of the active components of a motor. As a kit, the customer receives both the rotor and stator of the motor, providing them with the flexibility to seamlessly integrate the motor into their own mechanics or application. For more information, please visit our "Embedded Motion" technology page.

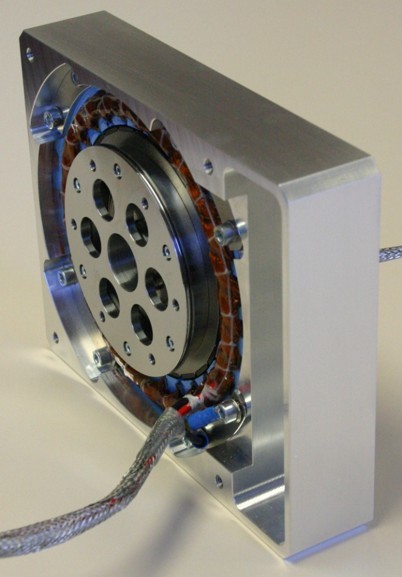

In many cases, kit motors are designed as torque motors. Torque motors are characterized by a specific geometry optimized for high torque rather than high power output. The form factor of a torque motor is typically short with a large diameter. This design choice helps to keep copper losses and electrical time constants of the motor low. Additionally, compared to conventional servo motors, these motors usually have more poles.

There are numerous reasons to utilize modern kit motors as a drive technology for both rotational and linear movements. The ability to flexibly integrate the motor into one's own mechanics enables optimized design and tailored solutions for specific requirements. Kit motors offer high power density, efficient energy transmission, and precise controllability. They are ideal for applications that demand high torque, such as machine tools, robotics, medical technology, and aerospace.

Furthermore, kit motors allow for direct power transmission without the need for additional mechanical translations or gearboxes, resulting in higher efficiency and accuracy. Due to their compact design and lack of housing, kit motors can also be accommodated in limited spaces.

The modern drive technology of kit motors provides a wide range of benefits and opens up new possibilities for implementing sophisticated motion applications. MACCON is proud to offer high-quality kit motors and assist customers in finding the optimal solution for their individual requirements.

There are a number of advantages to using this modern drive technology - both for rotatory and for linear motion control. It is not only a question of performance. Often secondary issues of mechanical assembly are of equal importance, such as:

- High acceleration capability

- High dynamic performance (ratio max./min. speed)

- Hetter stiffness and damping

- Hetter position accurarcy and repeatability

- High reliability

- High efficiency

- Good, consistant performance over a wide temperature range

- No wearing parts, long life

- Lower operational noise level

- Hollow shaft

- Short motor length or smaller cross-section

- Frame size or form