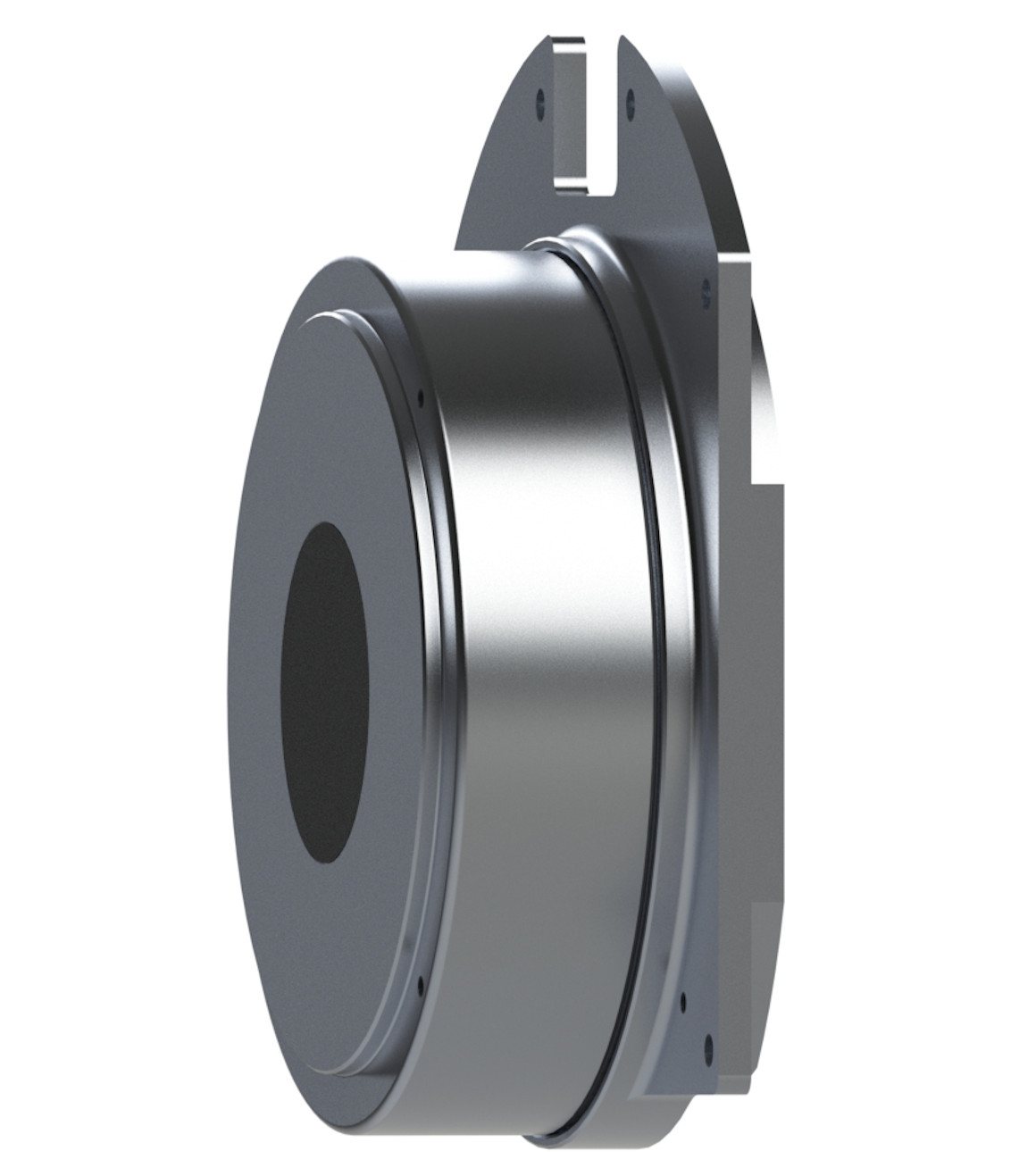

In some projects like e.g. Automated Guided Vehicles (AGV) there is limited space available for the drive motors, especially in the axial dimension. For such cases, flat motors are required. Our in-wheel XR series is a permanent magnet brushless motor with an external rotor. Permanent magnet brushless motors are generally the most efficient and highest torque density motors available today. The XR series gains from two distinct additional advantages: the magnets are positioned on an externally running rotor which gives the motor the fundamental geometric advantage that torque is being delivered on the outer-most point of the motor. Finally, the torque density of the XR series is maximised by a high degree of slot fill. The high slot fill is achieved by winding each of the stator teeth individually before assembling them together into a stator.

The stator teeth of the XR series are modular and interlock in such a way that we can vary the diameter and length of the stator more or less infinitely to fit both the packaging and the power requirements of the application. The in-wheel XR series can be liquid cooled or even oil filled for subsea applications that require underwater pressure compensation.

Applications for the XR Series in-motors include substitution of large high torque hydraulic actuation systems with a compact efficient motor, industrial and marine winch systems, propulsion of bomb disposal robots and other specialised military electric vehicles and trailers, traction for commercial electric vehicles for example in mining, direct drive radar systems, direct drive railway vehicles, compact generators for auxiliary power units, and general hybridisation of vehicle propulsion systems.